Supercars will end the engineering development race between teams with the introduction of Gen3 in a bid to significantly reduce running costs.

The arrival of the next-generation car is being heralded as a new era for the championship, which will put greater emphasis on driver skill and car set-up know-how.

A raft of components will be controlled by the category come 2022 such as front uprights and engines.

Those are two areas where teams have been allowed to build and develop and have become a sinkhole for teams to pour money into.

The introduction of Gen3 will see everyone running with more or less the same equipment, the only difference between teams being engine specification and body shape; either Camaro or Mustang.

Speaking with select media including Speedcafe.com, Supercars head of motorsport Adrian Burgess said removing the engineering arms race will provide two benefits.

One, that the teams will no longer be spending on parts development, and two, creating a level playing field between the haves and have nots.

“Part of the whole philosophy of the Gen3 car is to give everyone exactly the same product but give them something that’s adjustable,” Burgess explained.

“The engineers can make a difference or not, but they won’t be going away and changing a pickup point on an upright by five millimetres, costing themselves $50,000 in building new uprights.

“That side of the car and the programme should generate a fairly significant cost reduction for the teams and the amount of staff that it needs to operate the car.

“So what’s on the car; the uprights and the wishbones and the roll bars that are on the car on day one will be the same ones that are on the car five years later. They won’t be going away and continually re-engineering or redesigning any part of the car.

“It should come down to whoever’s done the best job on the day between the car engineer and driver and the team will have the best result. It won’t come down to the size of your chequebook and just turn into an arms race about developing a car.

“It’s not like Formula 1 where you’re bringing 30, 40, 50 developments to every Grand Prix. That’s not sustainable. As you can see in F1, they’re trying to bring in budget caps and the like.

“That era of motorsport is gone. We need to follow suit and we need to protect the teams and we need to deliver them with a car that’s cost-effective. It’s sustainable and then you don’t need an army of thousands and millions and millions [of dollars] to run the car.

“It’s one of the most expensive parts of our sport currently, is the development race that is allowed to go on,” he added.

“The size of the teams and the engineering departments is fairly significant. They’re always trying to change the car and improve it by the smallest margins and details, day in, day out.”

Like the incumbent Gen2 car, teams will be able to build cars themselves or buy them from a supplier.

Chevrolet homologation team Triple Eight Race Engineering currently supplies cars to Team 18, Team Sydney, and Matt Stone Racing.

Similarly, the Blanchard Racing Team is a customer of Ford squad Tickford Racing.

Burgess dismissed suggestions that Triple Eight Race Engineering and Ford homologation team Dick Johnson Racing would be the sole suppliers of the respective marques.

“The car is far more of a control car than we’ve ever seen in the past, which is a good thing, but they’re not coming out of one place,” Burgess said.

“This will be like a jigsaw puzzle. Everything will be designed for you. And there will be single-source suppliers of lots of components.

“That will only happen if it’s the right financial outcome for everybody, but anyone can go and put this car together.

“Equally, a small team that doesn’t have the manpower or resources to be building its cars, can go to a Tickford or a DJR or a Triple Eight or go anywhere and actually get those guys to put it together.

“But what they’re putting together is exactly the same as any other team will be able to put together. The only things that will be different will be body shape and the engine.

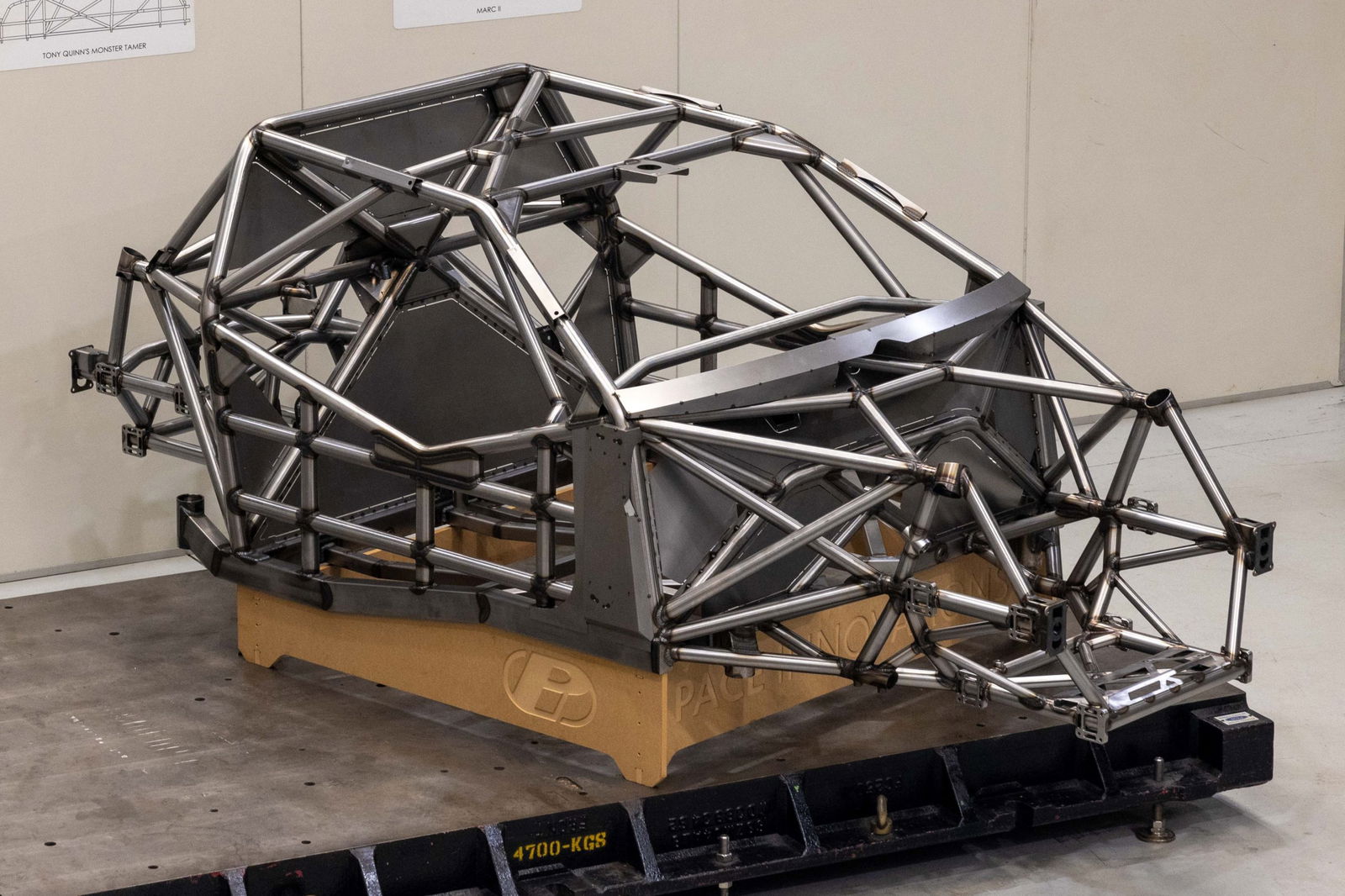

“Everything else will be exactly the same. They will all have control front suspension. All the cabin layout will be exactly the same. All the suspension, front and rear, all the kinematics. Everything will be controlled for them.

“The only thing the teams will need to worry about is what stickers they put on the outside of the thing. Apart from that, it will be a control car.”

While Supercars will remove development areas, Burgess is confident teams will have enough scope to make a difference on track with set-up changes.

“It will be a very adjustable control car – we don’t want to go down the route where everyone’s got exactly the same thing,” he explained.

“What we did with the rear suspension for Car of the Future when we made that a control component, we’re doing exactly the same on the front of the car.

“But it’s very adjustable, like the rear of the car is, because we want teams to be able to do a good job or a bad job. We still want people to go to a racetrack and it’s going to be the best team, driver, engineer combination that will come out on top.

“But equally, we want all the small teams to know that they’ve got exactly the same as the big teams have got, or the successful teams, and they’ve all got the same chances.

“It will create a very level playing field and it will be down to the teams. It won’t be an engineering or a financial race to go and buy an advantage that one team can have over another team. Everyone will have the same equipment.”

Discussion about this post